Request a Quote | Download Brochure

The new and improved Applied Test Systems (ATS) Bending Beam Rheometer 3S (BBR3S) has been designed to perform flexural tests on asphalt binder and similar specimens per AASHTO T 313, AASHTO TP 87, ASTM D6648, GOST 58400.8-2019, and BS EN 14771 specifications as part of the PG grading system according to Superpave. An ATS original, the BBR3S is the first of its kind to offer an internal computer system incorporating touch screen technology.

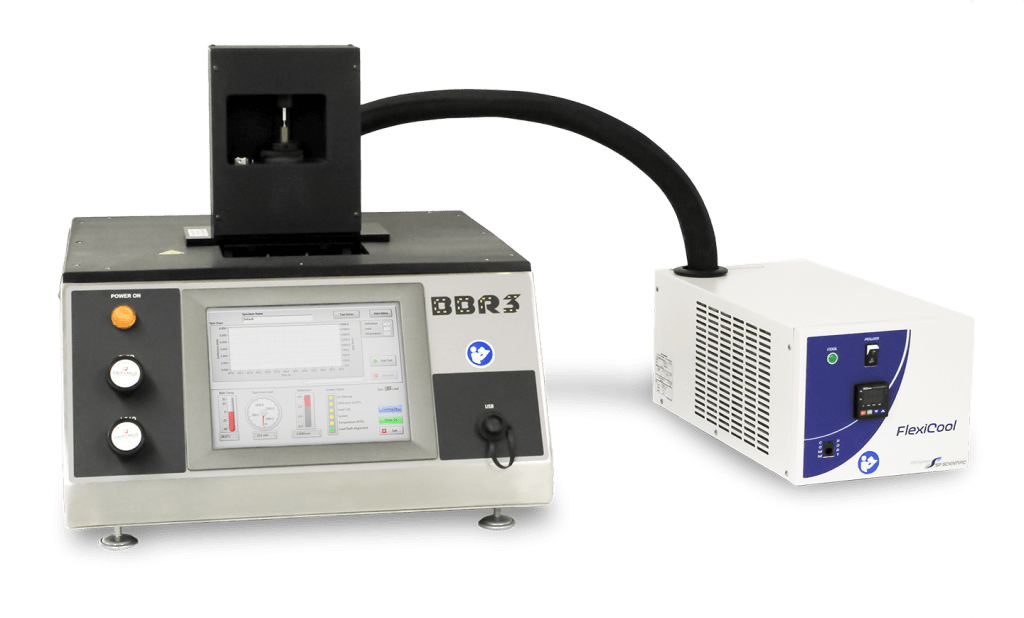

Each BBR3S consists of a fluid bath base with a built-in touchscreen computer, load frame, external refrigeration unit, and a calibration kit with carrying case. Used in part to determine a sample’s critical cracking temperature and low temperature PG grade, the BBR3S’s -40⁰C to 25⁰C temperature range is efficiently calculated by a platinum RTD measuring device. The 500g load cell and changeable specimen supports easily transition the BBR3S for crack sealant testing.

Designed to be user friendly and efficient, the BBR3S allows operators to enter a multitude of customizable test parameters. A built-in Ethernet connection allows users to monitor their equipment remotely using a tablet, smartphone, or other mobile device.

Features

- New and improved LVDT calibration disk and weight pan as well as an enhanced software update (2.8.1 and later).

- 12 inch, industrial strength touchscreen display

- Programmable test parameters include deflection plot, load plot, bath temperature, stirrer speed, specimen size, testing times, load, and testing company

- Changeable specimen supports easily transition for crack sealant testing

- Remote monitoring capabilities

- Compact external chiller with reduced noise during operation

- Customizable report settings – add a company logo, notes, and accreditations

- Seven pre-programmed language options include English, Spanish, German, French, Chinese, Italian, and Arabic

- Test data available in CSV and HTML.

Unit Includes

- Specimen Mold Kit for (5) Molds

- Aluminum casing bars, mylar strips, & holding bands

- 127 mm. lenght, with end piece location marks

- 6.4 mm thick, 12.7 mm wide

- Calibration Kit

- (1) Step disk & index

- (4) 50 gram weights

- (2) 2 gram weights

- (1) Confidence beam

- (1) Non-compliance beam

- Wooden storage case

- Crack Sealant Mold Kit for (6) Molds

- Holding bands

- Aluminum bars, end pieces, & plate

- (12) 165.00 mm x 19.00 mm Side Bar

- (12) 12.70 mm x 19.00 mm Spacer Bar

- (6) 177.00 mm 13.00 mm Bottom Plate

- Stylus & clip

Product Specifications

| Power Requirements | 230, 1ph, 50/60 Hz |

| Operating Temperature | Ambient to -40°C |

| Test Load | Variable test range from 0 to 4,000 mN standard. System. Maintains required test load within +/- 5mN throughout test cycle. |

| Test Cycle Times | Cycle times for pre-load, recovery, and test load are completely operator adjustable |

| Load Cell | 500g (temperature compensated) |

| LVDT Displacement Transducer | 6.35mm (0.25in) calibrated range to provide 2μm resolution throughout testing and verification range. |

| Recommended Cooling Bath Fluid | Non-flammable ethylene glycol mixture |

| Temperature Measurement | Platinum RTD |

| Compressed Air Requirements | 60 PSI inlet pressure (414 kpa) @ Class 3 Quality max particle of 5μm |

| Weight | Approximately 148 lbs. |

| Dimensions | 24” W x 23.5” H x 26.5” D |